The Single Strategy To Use For Premier Aluminum Llc

The Single Strategy To Use For Premier Aluminum Llc

Blog Article

The Basic Principles Of Premier Aluminum Llc

Table of ContentsSome Known Details About Premier Aluminum Llc Not known Details About Premier Aluminum Llc Things about Premier Aluminum LlcHow Premier Aluminum Llc can Save You Time, Stress, and Money.Premier Aluminum Llc for Dummies

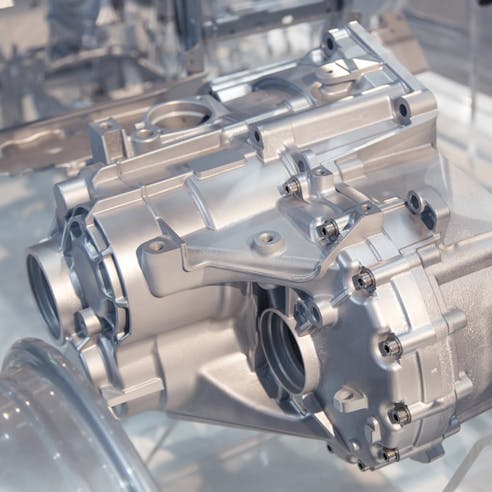

When selecting a light weight aluminum factory for your manufacturing demands, it's essential to examine a number of variables. One of the most important facets to consider is the experience and proficiency of the factory. Choosing a foundry that has the right knowledge of the aluminum spreading procedure, and the profile to show for it, assists to have an effective end result for your task.Having the experience and sector knowledge to craft your castings for ideal manufacturing and top quality results will improve the project. Making light weight aluminum spreading requires a complicated set of procedures to accomplish the appropriate outcomes. When choosing a brand-new aluminum factory to companion with, ensure they have considerable market experience and are educated regarding all elements of the aluminum spreading process: layout, production, product evaluation, and item screening.

The factory should also have a tried and tested record of supplying phenomenal items that satisfy or exceed client assumptions. Quality control needs to also be at the top of your checklist when picking a light weight aluminum factory. By working with a qualified factory that follows the criteria for top quality control, you can safeguard the stability of your item and ensure it meets your specs.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Various elements that very made complex forms can be made utilizing this process. Prior to you start searching for a reputable light weight aluminum pass away wheel, there are some vital points that you require to do.

You need to ask on your own what sort of light weight aluminum pass away spreadings you require. After identifying what you call for, you need to state the specs of the light weight aluminum pass away castings you require. Figure out the weight, density, size, and other specs of the light weight aluminum die-cast you call for. It would additionally be far better if you can attract and show all the measurements of the aluminum die-cast.

Do you recognize just how much money you have to invest on the items? In order to do this, the most effective point to do is to figure out exactly how many aluminum diecasts you call for. After having this information, you can start investigating light weight aluminum die-casting suppliers. You can do this by just keying the key phrase" Light weight aluminum die casting producers" on the Google search engine.

A few of the concerns you need to ask on your own are whether they have actually experienced and well-trained operators, exactly how long their company has actually been in procedure, or if they have some achievements. You can typically obtain the response to these concerns from the producer's web site. You can research various other sites or outside resources to verify if the information given on the supplier's internet site is authentic.

Examine This Report about Premier Aluminum Llc

An additional point you have to consider is the supplier's ability to generate aluminum die-casting items. Simply put, the quantity of products the maker can create at a provided time. Several of the crucial concerns you need to ask on your own are whether the producer can create a higher volume or can the maker fulfill your needs.

(https://forums.hostsearch.com/member.php?272804-premieraluminum)What happens if your company needs 10,000 items of specific device parts from the producer within one month? You bought this quantity; however, the supplier can just produce 5000 pieces of these equipment components within one month (Aluminum Metal casting). Therefore, you will not have the ability to get the quantity that you get on time

Premier Aluminum Llc for Dummies

It is vital that you should inquire if the producer is executing an internal tooling procedure. that site In addition, you need to ask the supplier just how much the expense of internal tooling is. The in-house tooling process, which permits you to produce unique styles and forms can be an additional price.

This element straight associates with the maker's production capacity. You have to seek a maker that can make certain quicker distribution of products. This need to be done in such a method that premium criteria are kept. This can assure that you can obtain your products in a timely manner, and you can stay clear of missing out on those beneficial organization opportunities.

This implies that there are a number of options that you can pick from. That is why it is substantially advised that you should pick a supplier that can create different kinds of aluminum die-cast products.

Some Of Premier Aluminum Llc

The majority of typically, these light weight aluminum die-casting items will call for some designs, machining, or finishing touches. Having this in mind, you should search for a supplier that can execute a variety of additional completing works once die spreading is done. Some examples of ending up operations include Chromating, CNC Machining, Sandblasting, Powder coating, Anodized, E-coating, Wet painting, Plating, and many even more.

Die casting is among the most cost-effective, precise, and protean manufacturing procedures on the planet moment. The procedure involves fitting molten significance, under pressure, into an appropriate die (earth), and formerly strengthened it can be ejected and completed (if necessary) in a variety of ways. The passes away are [...]. Report this page